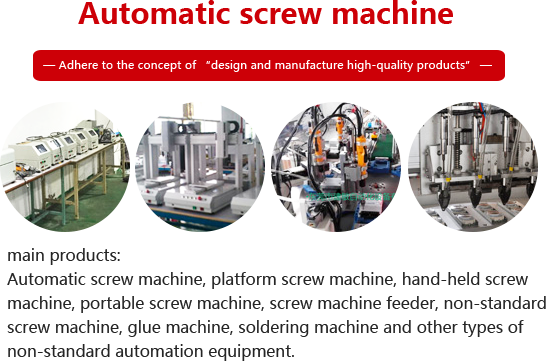

Generally speaking, the requirements of automatic lock screw machines for screws are mentioned. In most cases, they refer to the use range of air-blowing automatic nail feeders. Because the automatic lock screw equipment industry belongs to non-standard automatic equipment, the solution is designed according to the actual situation. There is no precise range, it can only be said that it can be used in certain situations, but in many cases, there is a suitable solution if it does not reach this range. Only by understanding the working principle of the automatic lock screw machine can we more clearly understand the scope of the equipment.

First, the automatic screw-locking machine needs to be equipped with an automatic nail feeder. The screws are arranged on the track through screening, and then the transmission signal is obtained, enter the feeder, through the nail feed tube, the screw is sent to the lock mouth by air pressure and the lock is paid. The transportation process mainly considers the screw arrangement and the nail delivery tube transportation.

1. Screw arrangement

The screws need to be neatly arranged on the track, waiting for the signal one by one and then transmitted. The screws are preferably independent individuals and cannot be locked together. This requires that the screws must not have burrs or movable washers, especially spring pads. sheet.

2. Automatic conveying

The screw conveying mainly passes through the distributor and the nail feeding tube. Here, the screw specification must not exceed M8. The screw feeding part requires that the screw cannot be reversed during the conveying process. This requires the total length of the screw to be greater than the diameter of the screw head. The direction is sent to the lock mouth, considering the bending of the nail feed tube and other factors, the total length of the screw is generally greater than 1.3 times the diameter of the screw head.

3. Automatic payment

The screw enters the lock mouth from the nail feed tube, and then the screwdriver head performs locking. The nail feed pipe and the lock mouth part need to be connected. Adjust the direction of the screw to ensure that the screw and the screwdriver head of the electric screwdriver are on the same straight line. If the screw is too long, the lock mouth The volume needs to be designed to be large in order to have enough space for the screw to adjust the position. If the lock mouth is too large, it is impossible to perform locking in many cases: there are other obstructions around the screw hole, deep hole screws, curved surface locking, etc., usually The screw length is less than 20mm in the design is not difficult, Jianmin automatic locking screw equipment can generally be applied to the total length of the screw is less than 40mm.